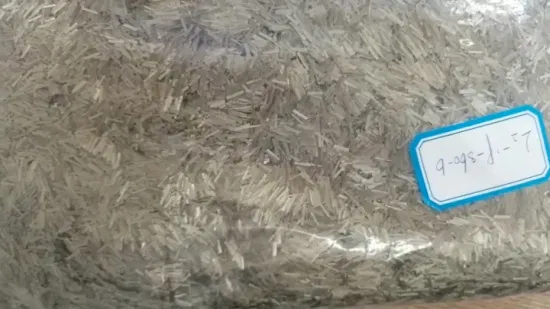

Low Temperature Crack Resistance Basalt Fiber for Construction

DESCRIPTION Chopped Basalt fiber is a product made continuous basalt fiber strands. The surface of the fiber coated with

Description

Basic Info.

| Hardness | 6moh |

| Density | 2.7g/Cm |

| Melt Point | >1450 |

| Transport Package | Bag |

| Specification | 16UM |

| Trademark | Leade |

| Origin | China |

| Production Capacity | 5000ton/Year |

Product Description

DESCRIPTIONChopped Basalt fiber is a product made continuous basalt fiber strands. The surface of the fiber coated with silane wetting agent. Therefore the choppered basalt fiber is an appropriate material to strengthen thermoplastic resin, and basalt fiber is also a material to strengthen concrete and needle-punched non-woven fabrics. Basalt is a high-performance component of volcanic rock This special silicate makes basalt fiber excellent alkali resistance.Therefore, basalt fiber is an excellent material to replace polypropylene (PP) and polyacrylonitrile (PAN) to strengthen cement concrete; it is also an alternative to polyester fiber, cellulose fiber for asphalt concrete, which can increase high temperature stability and low temperature crack resistance of asphalt concrete.

TECHNOLOGY PARAMETER

| Item | Parameter Range | |

| Fiber length(mm) | Average | 3mm~100mm |

| Fiber Diameter(μm) | Average | 9μm~25μm |

| Specific Area(M2/g) | Approximate:2.6M2/g | |

| Color | Yellow Brown | |

| Hardness | 6Moh | |

| Melt point(ºC) | >1450 | |

| Density(g/Cm) | 2.7±0.25 | |

FUNCTION

Reinforcing concrete beams with basalt fiber can defer the oblique cracks and restrain the development of oblique cracks, thereby improving the shear capacity, stiffness and deformation ability of the beam. The test results showed that the fatigue resistance of the beam was greatly improved basalt fiber additive. The fatigue life of reinforced concrete beams increased by 66% and 235% when basalt fiber added .Basalt fiber is a 100% mineral material, it will not form agglomerates in concrete, it is convenient to put into construction, and the price is lower than other fibers.

ADVANTAGE OF BASALT FIBER

1. Increase the amount of asphalt 2. Increased dynamic stability, improving high-temperature rutting resistance and fatigue resistance;3. Improve the resistance to temperature stress, reduce the occurrence of temperature shrinkage cracks, and improve the low-temperature crack resistance of the road surface;4. Improve the ability of asphalt pavement to resist early water damage;5. Improve the cohesive performance of the mixture;6. It is beneficial to improve the production efficiency and economic benefits of construction projects

Q: Are you a trading company or a manufacturer?

A: Manufacturer, welcome to our factory

Q: What are your products?

A: Polypropylene fiber, Polyester fiber, polyacrylonitrile fiber, PVA fiber, plastic steel fiber, anti-crack fiber, wood fiber, cellulose fiber, glass fiber, Steel fiber, carbon fiber, colorful wall coating fiber, anti-rutting agent, PSBR high modulus asphalt additive, asphalt warm mix agent, asphalt flame retardant, asphalt modifier,Anti-stripping agent, Sun shading mesh

Q: Are the samples free?

A: Accept free sample test, buyer bear delivery charge

Q: How can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q: What are your MOQ?

A: 1000KG Or More than 1000USD per order

Q: What is your delivery time?

A:Production will be arranged after receiving the deposit, and shipment will be arranged after all payments are made. The delivery time is about 10-15 working days.

Prev: E Glass Powder & Emulsion Fiberglass Chopped Strand Mat

Next: Kingcason Polyester Jacquard Knitted 3D Snowflake Christmas Sherpa Fabric for Blankets

Our Contact

Send now