Vacuum Infusion FRP Shell/Cover Veil Fiberglass Stitched Combo Mat for Pultrusion Surface Application

Description

Basic Info.

| Model NO. | HTDFM |

| Specification | 80-900 gsm |

| Trademark | HONTED |

| Origin | China |

| HS Code | 7019 |

| Production Capacity | 1800 Tons/Month |

Product Description

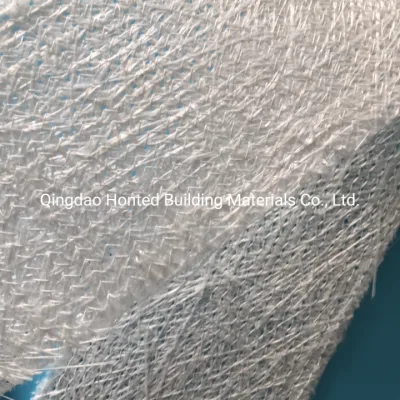

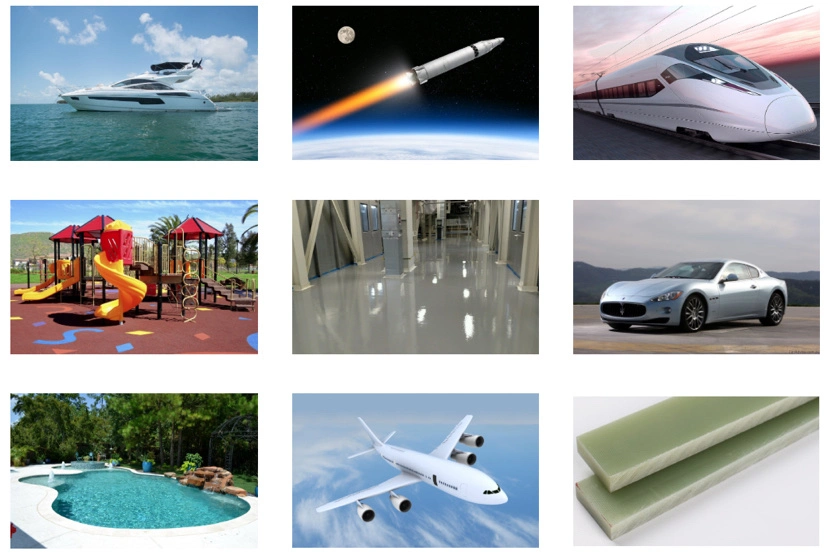

E Glass Fiberglass stitched mat is made of chopped fiberglass strands in a certain length, then freely put and stitched together with polyester tissue or carbon fiber tissue by polyester yarn. It is compatible with Polyester, Vinyl and Epoxy resin and widely used in pultrusion pipes and tanks, FRP boat, insulation panels, anode tubes, auto parts, bath tubes etc, suitable for pultrusion, filament winding, RTM, hand lay-up processes.

| Code | Weight(g/m2) | Chopped Strand(g/m2) | Polyester Yarn(g/m2) | Veil(g/m2) |

| HTM200 | 209.5 | 200 | 9.5 | / |

| HTM225 | 234.5 | 225 | 9.5 | / |

| HTM300 | 309.5 | 300 | 9.5 | / |

| HTMV300/45 | 354.5 | 300 | 9.5 | V30-45 |

| HTMC300/30 | 339.5 | 300 | 9.5 | C15-30 |

| HTM380 | 389.5 | 380 | 9.5 | / |

| HTMV380/45 | 434.5 | 380 | 9.5 | V45 |

| HTM400 | 409.5 | 400 | 9.5 | / |

| HTM450 | 459.5 | 450 | 9.5 | / |

| HTM600 | 609.5 | 600 | 9.5 | / |

| HTM900 | 909.5 | 900 | 9.5 | / |

E Glass Fiberglass Chopped Strand Mat (CSM) is a random fiber mat that provides equal strength in all directions and is used in a variety of hand lay-up and open-mold applications. Chopped strand mat is produced by chopping continuous strand roving into short 1.5 to 3 inch lengths and dispersing the cut fibers randomly over a moving belt to from a "sheet" of random fiber mat. A binder is applied to hold the fibers together and the mat is trimmed and rolled. Because of is random fiber orientation, chopped strand mat conforms easily to complex shapes when wet-out with polyester or vinyl ester resins. Chopped strand mats are available as a roll stock product produced in a variety of weights and widths to suite specific applications.

Emulsion Chopped Strand MatEmulsion Chopped Strand Mats are made of randomly distributed chopped strands held together by an emulsion binder. They are compatible with UP and VE resins. The roll width ranges from 200mm to 3,120mm. Special requirements may be available upon request.Powder Chopped Strand MatPowder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time can be available upon request.

| Product code | Weight (g/m2) | Binder content (%) | Water content (%) |

| CSM100 | 100 | 9-12 | <0.2 |

| CSM150 | 150 | 9-12 | <0.2 |

| CSM225 | 225 | 2-8 | <0.2 |

| CSM300 | 300 | 2-8 | <0.2 |

| CSM450 | 450 | 2-8 | <0.2 |

| CSM600 | 600 | 2-8 | <0.2 |

Density: 0.75 oz chopped strand mat 1.5 oz chopped strand mat 2.0 oz chopped strand mat 3.0 oz chopped strand matWidth: 4 inch, 6 inch, 38inch and 50 inch wide or as customers' requirement.

Features

Excellent weight uniformity

Fast wet out

Easy air releaseExcellent transparency of finished productsExcellent laminate clarityLow resin consumption

Related Products

| Products Cataloghttps://honted.en.made-in-china.com/product-list-1.html |

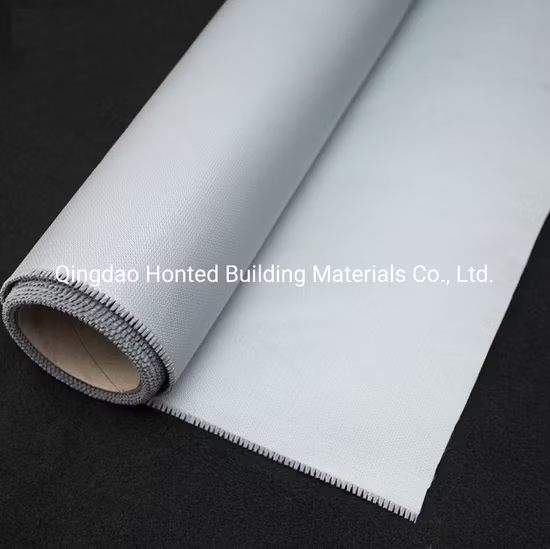

| WOVEN ROVING |

| STITCHED MAT |

| COMBO MAT |

| CHOPPED STRAND MAT |

| MULTI-AXIAL FABRIC |

| SURFACING TISSUE |

| FIBERGLASS ROVING |

| CARBON FIBER FABRIC |

Production

Packing and Shipping

Plastic film + carton Non wooden Pallet Container Loading

Storage

Unless otherwise specified, the fiberglass products should be in dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15ºC~35ºC and 35%~65%. It is best if the price is used within 12 months after production date. The fiberglass products should remain in their original packaging until just prior to user.

Application

FAQs

1. What is your terms of packing?

Generally, we pack our goods in carton with pallet

2. What is your tems of payment?

T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.3. What is your terms of delivery?

EXW, FOB, CFR, CIF,L/C at sight4. How about your delivery time?

Generally, it will take 21 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.5. Can you produce according to the samples? Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

6. What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

24 Hours Services Choose us, you will get the key of market!Contact us, we will use the professional knowledge serve you!Wish we can create the great future together!

Prev: Udl950/V30 Centrifugal Casting, Stitched Combo Mat on 0

Next: Fiberglass Stitched Woven Roving Combo Mat Wrm800/300 for Hand Lay up

Our Contact